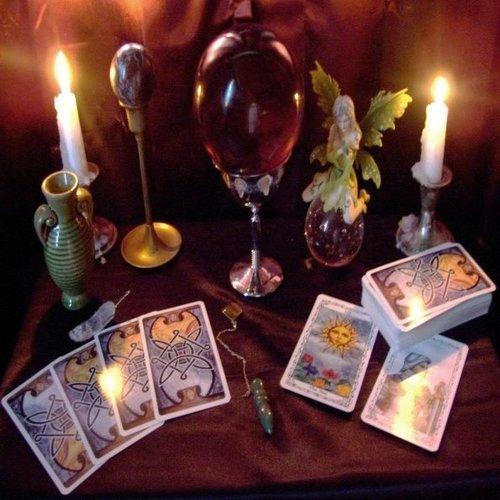

Love is a journey, filled with moments of excitement, curiosity, and sometimes uncertainty. Embracing joy and confidence in love requires self-awareness, openness, and guidance from gentle experiences that illuminate your heart. Psychic readings, approached with care and positivity, can offer insights that enhance emotional clarity and foster deeper connections. Here’s how you can nurture love through gentle psychic guidance.

Discover Clarity and Understanding

Gentle psychic readings provide a safe and supportive space to explore your feelings and desires. By tuning into intuitive insights, you can:

- Gain clarity about your emotional needs, helping you recognize what truly matters in your relationships.

- Understand patterns and behaviors, both in yourself and in those you care about, fostering compassion and empathy.

- Identify opportunities for growth, allowing you to approach love with confidence and intentionality.

Understanding yourself deeply is the first step toward building fulfilling and joyful relationships. Psychic readings can gently highlight your strengths, offering reassurance and guidance along the way. A love psychic reading can transform uncertainty into clarity, offering guidance to make choices that promote lasting love and happiness.

Boost Confidence in Love

Confidence is magnetic in the realm of love. Through thoughtful psychic experiences, you can cultivate self-assurance by:

- Recognizing your inherent worth, embracing your unique qualities and the love you deserve.

- Receiving gentle affirmations, which reinforce your ability to give and receive love freely.

- Navigating uncertainty with calm, allowing you to face romantic challenges without fear or hesitation.

When you feel confident in yourself, you naturally attract healthier and more meaningful connections. Gentle psychic guidance helps you step into love with optimism and self-belief.

Foster Joy and Emotional Fulfillment

Love is most rewarding when it brings joy and emotional satisfaction. Psychic readings can enhance your happiness by:

- Encouraging mindful presence, helping you appreciate each moment with your partner.

- Highlighting potential paths for joy, inspiring optimism and hope in your love life.

- Promoting emotional healing, guiding you to release past wounds and embrace love fully.

By focusing on positive outcomes and inner joy, psychic readings help you nurture a heart that is open, vibrant, and ready for connection.

Practical Tips for Embracing Love Through Psychic Experiences

To make the most of your journey:

- Approach readings with an open mind and a heart full of curiosity.

- Reflect on the insights received, integrating them into your daily interactions.

- Trust your intuition while balancing guidance with your personal judgment.

- Celebrate small victories in love and acknowledge your progress.

Gentle psychic experiences are not about predicting the future but about empowering you to embrace the present with joy, clarity, and confidence. Love flourishes when nurtured with self-awareness, positivity, and emotional courage. Through gentle psychic reading experiences, you can gain clarity, boost confidence, and cultivate joy in your romantic journey. By embracing guidance with an open heart, you create space for meaningful connections and a love life filled with happiness and fulfillment.