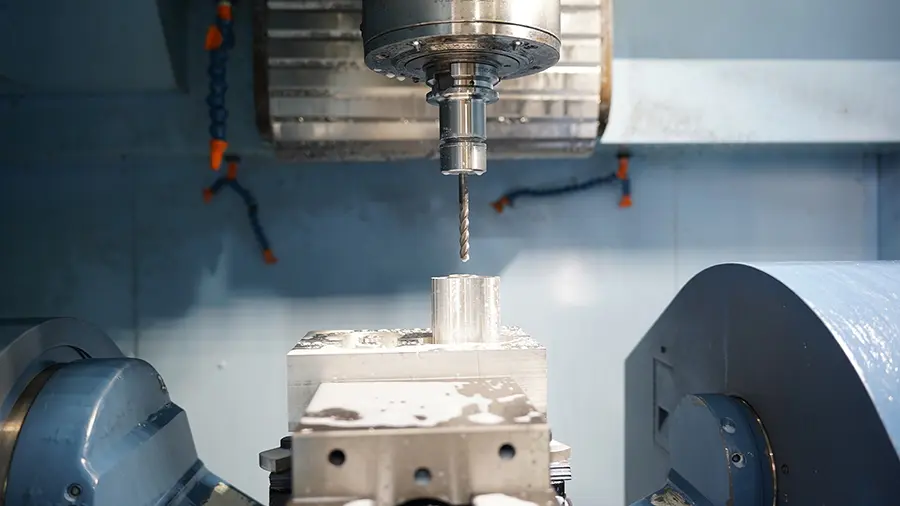

In the world of precision manufacturing, achieving high surface quality and exact dimensional accuracy is crucial. CNC grinding technology has emerged as a reliable and efficient method to meet these demands. This advanced process not only enhances product consistency but also streamlines production for industries focused on detail-oriented components.

What is CNC Grinding?

Uneed CNC Computer Numerical Control grinding is a machining process that uses a rotating grinding wheel to remove material from a workpiece. Unlike traditional grinding, CNC machines are programmed with exact movements and parameters, ensuring a high level of automation, consistency, and precision.

Key Advantages of CNC Grinding

- Superior Surface Finish

CNC grinding achieves extremely smooth surface finishes, even on hard materials such as hardened steel, ceramics, and composites. This makes it ideal for manufacturing parts that require minimal friction or contact wear.

- Unmatched Dimensional Accuracy

Precision is a defining feature of CNC grinding. By using high-resolution controls and servo motors, machines can grind parts to tolerances within microns. This level of accuracy is essential in industries like aerospace, medical device manufacturing, and automotive production.

- Consistent Quality at Scale

With repeatable and automated programming, CNC grinding ensures each piece produced is identical in quality. This consistency greatly reduces inspection times and enhances batch production reliability.

- Versatility across Applications

Whether working with internal diameters, external surfaces, or complex profiles, CNC grinders can be adapted with different wheel types, tool heads, and support fixtures to meet various manufacturing needs.

- Improved Efficiency and Reduced Waste

CNC grinding systems minimize human error and material loss by optimizing every movement. This not only saves costs but also supports sustainability goals in modern production environments.

Applications across Industries

CNC grinding is widely used in sectors that demand exceptional component reliability. Common applications include:

- Engine and transmission parts in automotive

- Surgical instruments and implants in healthcare

- Precision molds and tools in industrial engineering

- High-tolerance components in defense and aerospace

Future-Ready Technology

With the integration of IoT and machine learning, CNC grinding machines are becoming even smarter. Real-time monitoring, adaptive feedback, and predictive maintenance are now improving uptime and performance. Manufacturers adopting such innovations are preparing their operations for the future of Industry 4.0.

Why CNC Grinding is a Strategic Investment

Companies seeking a competitive edge are increasingly turning to CNC grinding technology for:

- Shorter lead times

- Reduced rework and defects

- High repeatability for mass production

- Enhanced product quality

One such manufacturing facility recently integrated this technology into its workflow, aligning with the advanced practices of a name associated with precision and progress. Their commitment to quality showcases the transformative power of CNC grinding when applied with innovation and care.

In Summary

CNC grinding technology is redefining what is possible in surface quality and dimensional precision. Its ability to deliver consistent, high-quality results with efficiency makes it an indispensable tool in modern manufacturing. Embracing this technology means investing in quality, accuracy, and long-term production success.