Injection molding, a pivotal manufacturing process for producing complex plastic parts, is undergoing significant transformation driven by the dual imperatives of sustainability and technological advancement. These changes are not only reshaping the industry but also aligning it with global environmental and efficiency standards. Among the most notable trends are the increasing use of sustainable materials and the integration of smart manufacturing technologies. One of the primary trends in injection molding is the shift towards sustainable materials. Traditionally, the industry has relied heavily on petroleum-based plastics, which contribute to environmental degradation due to their non-biodegradable nature. However, there is a growing demand for biodegradable and bio-based plastics derived from renewable sources such as corn starch, sugarcane, and cellulose. These materials not only reduce the carbon footprint of the products but also offer end-of-life benefits such as compost ability. Innovations in material science are leading to the development of high-performance biopolymers that match or even exceed the properties of traditional plastics, ensuring that sustainability does not come at the cost of quality or functionality.

Recycling and reusability are also key aspects of sustainability in injection molding. The industry is increasingly adopting closed-loop systems where plastic waste generated during the manufacturing process is collected, reprocessed, and reused. Advanced sorting and processing technologies enable the efficient separation and recycling of different types of plastics, thereby minimizing waste. Moreover, the use of recycled plastics is gaining traction, driven by both regulatory pressures and consumer demand for eco-friendly products. Companies are investing in technologies that enhance the quality of recycled plastics, making them suitable for high-end applications. Parallel to the shift towards sustainable materials is the integration of smart manufacturing technologies, which is revolutionizing the injection molding process. Smart injection molding companies leverages the Internet of Things IoT, artificial intelligence AI, and data analytics to optimize production processes, enhance product quality, and reduce downtime. IoT-enabled sensors and devices collect real-time data from the production floor, which is then analyzed to monitor equipment performance, predict maintenance needs, and identify inefficiencies. This predictive maintenance approach minimizes unexpected breakdowns and extends the lifespan of machinery, leading to cost savings and improved operational efficiency.

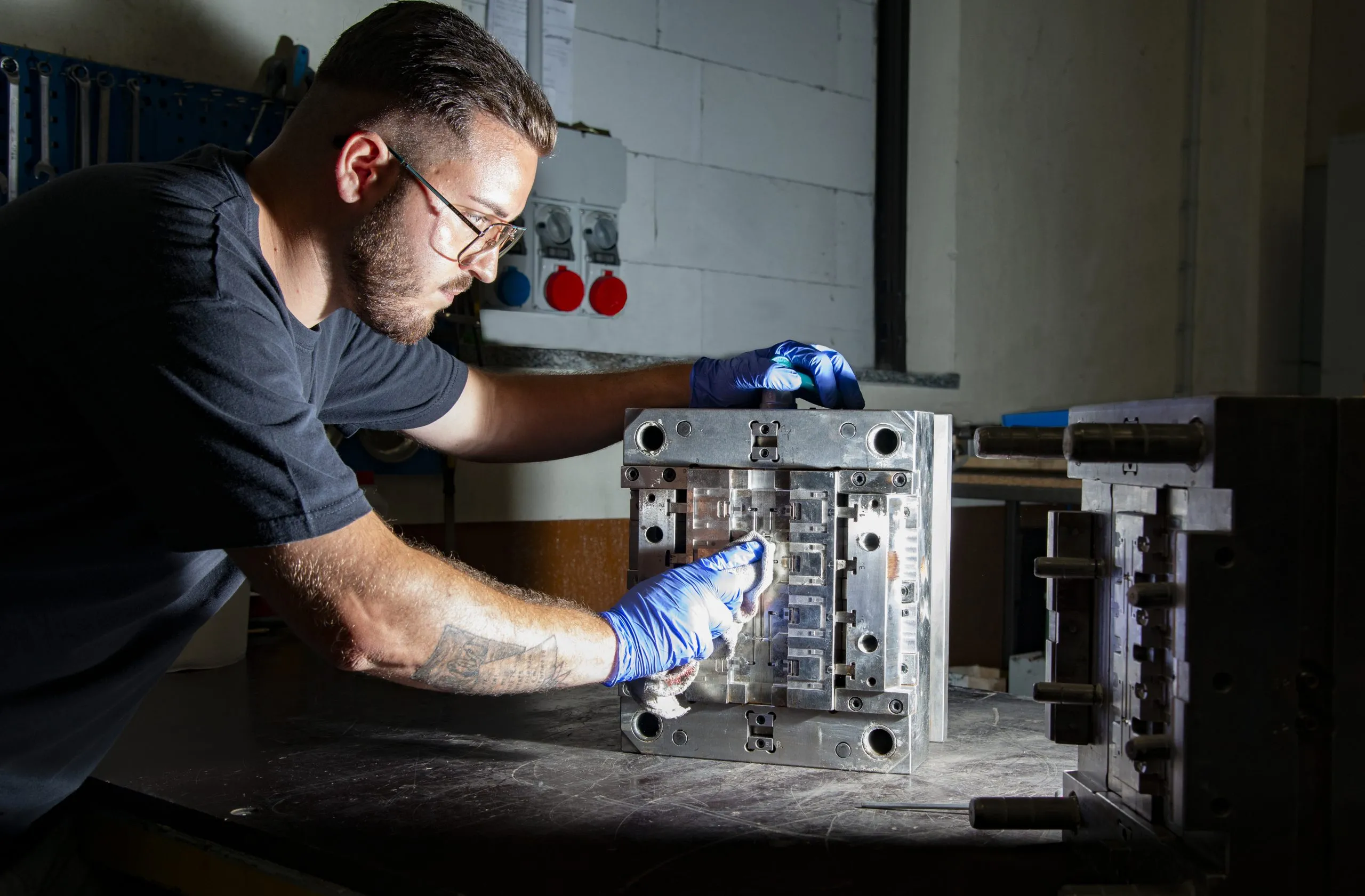

AI and machine learning algorithms are being employed to analyze vast amounts of data generated during the injection molding process. These technologies can predict defects, optimize mold designs, and adjust process parameters in real-time to ensure consistent product quality. Automation is another critical component of smart mold manufacturing, with robotic systems being used to handle repetitive tasks, thus freeing up human operators for more complex and value-added activities. Collaborative robots, or cobots, work alongside human workers to enhance productivity and safety on the production line. The convergence of sustainable materials and smart manufacturing technologies is setting the stage for a more resilient and eco-friendly injection molding industry. By adopting biodegradable and recyclable materials, manufacturers are reducing their environmental impact and meeting the growing demand for sustainable products. Meanwhile, the implementation of smart manufacturing practices is driving efficiency, reducing costs, and improving product quality.